In the intricate ecosystem of modern healthcare, few elements are as fundamentally vital as a reliable hospital oxygen supply system. Oxygen, often considered a drug, is indispensable for a vast spectrum of medical interventions, from routine patient care to life-saving critical procedures. Its constant, uncompromised availability directly correlates with positive patient outcomes, operational efficiency, and, ultimately, the very accreditation of a medical institution. The transition from reliance on external cylinder deliveries to on-site generation through Pressure Swing Adsorption (PSA) technology represents a paradigm shift, offering unparalleled advantages in terms of cost-effectiveness, security of supply, and environmental sustainability. A state-of-the-art oxygen supply system is no longer merely a utility; it is a strategic asset that underpins the capacity of a hospital to deliver high-quality, uninterrupted care, especially in scenarios of escalating demand or supply chain disruptions. This foundational infrastructure ensures that every breath taken by a patient, supported by medical intervention, is backed by a system designed for precision, purity, and unwavering reliability. Its role extends beyond just life support, impacting surgical procedures, respiratory therapies, and emergency response, making it an undeniable cornerstone of contemporary medical practice.

The Unprecedented Demand: Data Driving the Need for Robust Oxygen Infrastructure

The global healthcare landscape has witnessed an exponential surge in demand for medical oxygen, a trend underscored by sobering statistics and evolving medical requirements. Respiratory diseases, including chronic obstructive pulmonary disease (COPD), asthma, pneumonia, and acute respiratory distress syndrome (ARDS), collectively account for an estimated 6.4% of all hospital admissions globally, with a disproportionately higher need for oxygen support in critical cases. For instance, data from the World Health Organization indicates that approximately 15% of all COVID-19 patients required oxygen therapy, while 5% needed mechanical ventilation, placing immense strain on existing oxygen infrastructures worldwide. Furthermore, the aging global population is driving an increase in age-related chronic conditions, projected to elevate the need for long-term oxygen therapy by an additional 10-15% annually in many developed nations. In emergency scenarios, such as natural disasters or pandemics, the demand can spike by an astounding 300-500% within days, often overwhelming traditional supply chains reliant on liquid oxygen deliveries or bottled cylinders. These figures are not mere abstractions; they represent critical moments where the adequacy of an oxygen supply system directly impacts survival rates and recovery trajectories. Investing in a resilient, scalable, and on-demand oxygen generation system is therefore not just a matter of operational improvement but a strategic imperative to safeguard public health and ensure preparedness for future crises. The economic implications are equally profound; a study revealed that hospitals relying on cylinder oxygen could reduce their operational costs by up to 60-70% by transitioning to on-site PSA generation, translating into significant savings that can be reinvested in patient care.

Technological Edge: Unpacking the Advantages of Advanced Oxygen Generation

Modern hospital oxygen supply systems leverage sophisticated technologies, primarily Pressure Swing Adsorption (PSA), to deliver medical-grade oxygen with remarkable efficiency and reliability. The core principle of PSA involves separating oxygen from compressed ambient air by selectively adsorbing nitrogen, argon, and other gases onto a molecular sieve material. This cyclical process, operating under varying pressures, produces oxygen of 93% ± 3% purity, meeting stringent international pharmacopoeia standards (e.g., USP, EP). Key technological advantages include:

· Uninterrupted Supply Security: Unlike external deliveries susceptible to logistical delays, road closures, or supplier shortages, an on-site PSA system guarantees a continuous, independent supply. This autonomy is crucial during emergencies, ensuring patient care remains uncompromised.

· Cost Efficiency: Over the long term, generating oxygen on-site is significantly more cost-effective. Eliminating procurement, transportation, and storage costs associated with cylinders or liquid oxygen results in substantial operational savings. A typical PSA system can reduce oxygen expenses by 50-70% compared to traditional methods.

· Enhanced Safety Profile: On-site generation eliminates the hazards of storing large volumes of high-pressure cylinders or cryogenic liquid oxygen, reducing risks of leaks, fires, and explosions. The systems are designed with multiple safety interlocks and alarm protocols.

· Scalability and Modularity: Advanced systems are modular, allowing for future expansion as hospital capacity grows. Additional generator modules can be easily integrated without disrupting existing operations, ensuring the system evolves with demand.

· Remote Monitoring and Control: State-of-the-art systems incorporate sophisticated PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) systems, enabling real-time monitoring of oxygen purity, pressure, flow rate, and operational status from a central control room or even remotely via secure networks. This allows for proactive maintenance and rapid response to any operational deviations.

· Energy Efficiency: Modern PSA generators are engineered for optimal energy consumption, utilizing advanced molecular sieve materials and optimized cycle times to minimize power usage per liter of oxygen produced, contributing to lower utility bills and a reduced carbon footprint.

· Purity Assurance: Continuous online oxygen purity analyzers provide real-time validation, ensuring the oxygen consistently meets medical-grade specifications. Backup systems and automatic switchovers guarantee uncompromised purity even during maintenance.

· Reduced Environmental Impact: By eliminating the need for frequent transportation of heavy gas cylinders, on-site generation significantly reduces carbon emissions associated with logistics, contributing to the hospital's sustainability goals.

These technological advancements transform oxygen supply from a logistical challenge into a seamless, integral utility, empowering hospitals to focus squarely on patient care.

Strategic Selection: A Comparative Analysis of Leading Hospital Oxygen System Manufacturers

Choosing the right manufacturer for a hospital oxygen supply system is a critical decision impacting long-term operational efficiency, patient safety, and budget. While many companies offer PSA oxygen generators, their offerings can vary significantly in terms of technology, reliability, support, and total cost of ownership. A thorough comparative analysis is essential. Below is a hypothetical comparison of three types of manufacturers—a global leader, a specialized innovator, and a cost-effective regional provider—across key performance indicators:

|

Feature/Manufacturer |

Global MedTech (e.g., Parker, Atlas Copco) |

Purity Oxygen Solutions (Specialized Innovator) |

Innovate Gas Systems (Regional Provider) |

|

Oxygen Purity Guarantee |

93% ± 3% (exceeds USP/EP, consistent) |

93% ± 3% (robust real-time monitoring) |

90-95% (may have slight fluctuations) |

|

System Capacity Range |

Extensive (10 – 10,000+ LPM), scalable |

Medium-Large (50 – 5,000 LPM), modular |

Small-Medium (20 – 1,000 LPM), fixed configurations |

|

Energy Efficiency (kWh/m³ O₂) |

Excellent (0.8 – 1.2 kWh/m³) with advanced control |

Very Good (1.0 – 1.4 kWh/m³) with optimized cycles |

Good (1.3 – 1.8 kWh/m³) standard components |

|

Remote Monitoring & Control |

Advanced PLC/HMI, IoT integration, predictive maintenance |

Comprehensive web-based interface, alerts |

Basic local controls, limited remote options |

|

Maintenance & Support Network |

Global footprint, 24/7 support, extensive spare parts |

Strong regional/national presence, specialized technicians |

Local support, potentially longer lead times for parts |

|

Initial Capital Investment |

Higher (premium for brand, advanced features) |

Moderate (balanced tech and value) |

Lower (competitive pricing, standard offerings) |

|

Total Cost of Ownership (TCO) |

Lowest (due to efficiency, longevity, low downtime) |

Low-Moderate (good balance of efficiency and maintenance) |

Moderate-High (potentially higher energy/maintenance) |

|

Customization & Integration |

Highly customizable, seamless BMS integration |

Good flexibility for tailored solutions |

Limited customization, standard interfaces |

This comparison highlights that while initial cost is a factor, long-term TCO, reliability, and robust support are paramount for a critical infrastructure like medical oxygen. Hospitals must evaluate manufacturers not just on price, but on their proven track record, technological sophistication, after-sales service, and the ability to integrate seamlessly with existing hospital infrastructure and future expansion plans.

Tailored Solutions: Designing Bespoke Oxygen Supply Architectures for Healthcare Facilities

A "one-size-fits-all" approach simply does not suffice for hospital oxygen supply systems. Each healthcare facility possesses a unique set of demands influenced by patient volume, specialization, geographical location, existing infrastructure, and future expansion plans. Consequently, designing a bespoke oxygen supply architecture is crucial for optimizing performance, ensuring compliance, and maximizing return on investment. The process begins with a comprehensive needs assessment, meticulously evaluating current and projected oxygen consumption rates across different departments—intensive care units (ICU), operating theaters, emergency rooms, general wards, and long-term care facilities. This assessment also considers peak demand scenarios, such as multiple concurrent surgeries or mass casualty incidents.

Key customization parameters include:

· Capacity and Redundancy: Determining the optimal generator size and implementing redundancy (e.g., N+1 configuration with backup cylinder manifolds or liquid oxygen tanks) ensures uninterrupted supply even during maintenance or unexpected outages. This prevents critical care disruptions and upholds patient safety standards.

· Purity Requirements: While 93% ± 3% is standard, some specialized applications might require slightly different purities, influencing molecular sieve selection and system design.

· Space Constraints and Installation: Hospitals often face limited real estate. Custom solutions can involve containerized units for outdoor installation, compact indoor designs, or even modular systems that can be integrated into existing plant rooms, minimizing disruption to operations.

· Energy Infrastructure Integration: Designing the system to integrate seamlessly with the hospital's existing electrical grid, potentially incorporating energy-saving features like variable speed drive (VSD) compressors, optimizes power consumption and reduces operating costs.

· Piping and Distribution Network: Customizing the medical gas pipeline system (MGPS) to meet specific facility layouts, ensuring correct pipe sizing, material selection, and pressure regulation at every point of use, is critical for safe and efficient delivery. This includes considerations for future extensions to new wings or departments.

· Monitoring and Control System Integration: Integrating the oxygen plant's PLC and HMI with the hospital's Building Management System (BMS) or SCADA allows for centralized monitoring, alarm management, and data logging, providing a holistic view of facility operations.

· Environmental Adaptations: For facilities in extreme climates, specialized air intake filtration, cooling systems, or heating elements may be incorporated to ensure optimal performance and longevity of the oxygen generator components.

· Compliance and Certification: Tailored solutions ensure strict adherence to local and international medical device regulations (e.g., ISO 13485, HTM 02-01, FDA), pharmacopoeia standards, and building codes, mitigating compliance risks.

Through this meticulous customization, a hospital can acquire an oxygen supply system that is not only robust and reliable but also perfectly aligned with its operational workflows, budgetary constraints, and long-term strategic goals, providing maximum value and peace of mind.

Real-World Impact: Case Studies in Optimized Medical Oxygen Delivery

The successful implementation of advanced hospital oxygen supply systems transforms healthcare delivery, demonstrating tangible benefits across diverse settings. Here are three hypothetical case studies illustrating the profound impact of tailored oxygen solutions:

Case Study 1: The Metropolitan Teaching Hospital – Enhancing Resilience and Cost-Efficiency

Challenge: Metropolitan General Hospital, a 1200-bed urban teaching facility, relied entirely on liquid oxygen (LOX) deliveries. This presented logistical challenges, high monthly costs averaging $150,000, and vulnerability to supply chain disruptions, particularly during city-wide events or adverse weather. Their projected growth required a more resilient and sustainable solution.

Solution: The hospital invested in a dual-line, high-capacity PSA oxygen generation system with an N+1 redundancy configuration, capable of producing 1500 LPM (liters per minute) of 93% oxygen. It was integrated with their existing LOX bulk tank, which now serves as a tertiary backup. The system was designed with advanced remote monitoring capabilities, feeding data directly into the hospital's central BMS.

Impact: Within the first year, the hospital reported a 65% reduction in oxygen procurement costs, saving approximately $1.17 million annually. Furthermore, the system demonstrated critical resilience during a severe winter storm that halted road transport for 72 hours; the on-site generators operated flawlessly, ensuring uninterrupted oxygen supply to over 200 critically ill patients. The staff also noted a significant reduction in administrative burden related to LOX ordering and inventory management.

Case Study 2: The Remote Community Clinic – Bridging Access Gaps

Challenge: A small community clinic serving a remote, mountainous region struggled with unreliable and expensive oxygen cylinder deliveries. Cylinders were often delayed, costly to transport, and frequently ran out during peak patient times, forcing transfers to distant urban hospitals for basic respiratory care.

Solution: A compact, containerized PSA oxygen system with a capacity of 100 LPM was installed on the clinic grounds. The self-contained unit included a dedicated air compressor, filtration, oxygen generator, and a small buffer tank, operating autonomously. Its robust design was chosen for minimal maintenance requirements suitable for a remote location.

Impact: The clinic achieved complete self-sufficiency in oxygen supply. Patient transfers for oxygen-dependent conditions dropped by 80%, allowing more patients to receive timely care within their community. The cost of oxygen decreased by over 75%, redirecting funds towards other essential medical supplies. The reliability of oxygen availability transformed the clinic's capacity to manage common respiratory ailments and stabilize emergency cases before potential transfer.

Case Study 3: The Specialized Pediatric Hospital – Purity and Precision

Challenge: A specialized pediatric hospital required exceptionally stable oxygen purity and pressure for its neonatal intensive care unit (NICU) and complex pediatric surgeries. Fluctuations common with older manifold systems were a concern, and precise flow control for vulnerable patients was paramount.

Solution: The hospital implemented a state-of-the-art PSA system featuring a dual-stage filtration and purification process to achieve tighter purity tolerance. It was integrated with an advanced medical gas manifold system that provided precise pressure regulation and flow control at individual patient points. The system also included redundant purity analyzers and automatic fail-safes to ensure consistent quality.

Impact: The NICU reported unprecedented stability in oxygen delivery, leading to improved ventilator synchronization and reduced stress on delicate respiratory systems. An audit showed zero instances of oxygen supply interruption or purity deviation over two years. Surgeons praised the consistent gas quality, which minimized risks during long and intricate procedures. The system's quiet operation also contributed to a calmer healing environment for young patients.

Pioneering the Future of Healthcare with Integrated Hospital Oxygen Supply Systems

The journey from traditional oxygen procurement to advanced, on-site generation through a sophisticated hospital oxygen supply system marks a pivotal evolution in healthcare infrastructure. It is a strategic shift that prioritizes patient safety, operational resilience, and financial prudence. The intricate balance of technological innovation, meticulous planning, and tailored implementation ensures that medical oxygen, a fundamental element of care, is delivered with unwavering reliability and purity. As healthcare faces escalating demands, driven by demographic shifts, emerging infectious diseases, and the increasing complexity of medical treatments, the robustness of a hospital's oxygen infrastructure will only grow in importance. Investing in a cutting-edge oxygen supply system is not merely an upgrade; it is an investment in the foundational capacity of a hospital to deliver life-saving care consistently and efficiently. It empowers healthcare providers with autonomy, reduces environmental impact, and significantly lowers long-term operating costs, redirecting precious resources back into patient services and research. Ultimately, an optimized hospital oxygen supply system stands as a testament to a facility's commitment to excellence, prepared for current challenges and resilient against future uncertainties, ensuring that every patient receives the breath of life they critically need.

Frequently Asked Questions (FAQ) about Hospital Oxygen Supply Systems

What is a hospital oxygen supply system?

A hospital oxygen supply system is a critical infrastructure within a healthcare facility designed to generate, store, and distribute medical-grade oxygen to patients. Modern systems typically utilize Pressure Swing Adsorption (PSA) technology to produce oxygen on-site from ambient air, eliminating reliance on external deliveries of oxygen cylinders or liquid oxygen.

What are the primary benefits of an on-site PSA oxygen generation system for hospitals?

Primary benefits include significant cost savings (up to 70% compared to traditional methods), enhanced supply security and independence, reduced logistical complexities, improved safety by minimizing high-pressure cylinder storage, environmental benefits from reduced transportation, and scalability to meet fluctuating demand.

What purity level does medical-grade oxygen from a PSA system achieve?

On-site PSA oxygen generation systems typically produce oxygen with a purity of 93% ± 3%. This purity level meets stringent international pharmacopoeia standards, such as those set by the United States Pharmacopeia (USP) and European Pharmacopoeia (EP), making it entirely suitable for medical applications.

How does a hospital ensure the reliability of its on-site oxygen supply?

Reliability is ensured through several mechanisms: redundant generator modules (e.g., N+1 configuration), backup oxygen sources (e.g., a manifold of high-pressure cylinders or a small liquid oxygen tank), real-time purity and pressure monitoring with automatic alarm systems, and comprehensive maintenance contracts with the manufacturer.

Can an on-site oxygen system be integrated with existing hospital infrastructure?

Yes, modern on-site oxygen systems are designed for seamless integration. They connect to the hospital's existing medical gas pipeline system (MGPS) and can often be linked to the hospital's Building Management System (BMS) for centralized monitoring and control, ensuring compatibility and efficient operation.

What factors should a hospital consider when choosing an oxygen supply system?

Key factors include projected oxygen demand (peak and average), required purity, available space for installation, budget (initial capital and long-term operating costs), manufacturer's reputation, maintenance and support services, energy efficiency, scalability for future expansion, and adherence to local and international medical gas standards.

What is the typical lifespan and maintenance requirement for a PSA oxygen generator?

With proper maintenance, a high-quality PSA oxygen generator can have a lifespan of 15-20 years or more. Routine maintenance typically involves regular checks of filters, air compressors, and valves, as well as periodic replacement of molecular sieve material (every 5-10 years, depending on usage and air quality). Most manufacturers offer comprehensive service contracts.

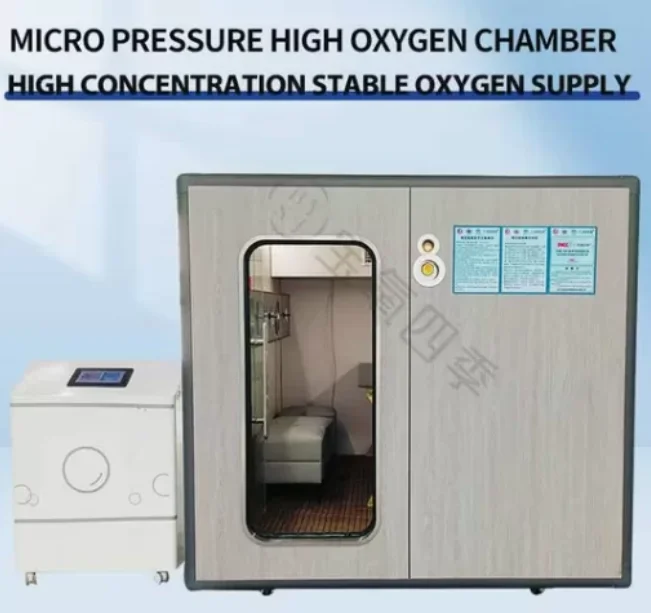

Hebei Lixin Medical Engineering Co., Ltd. was established in 2011. medical oxygen generator manufacturers The company specializes in the production and sales of medical central gas supply systems,medical oxygen generator manufacturers medical molecular sieve oxygen generation equipment, medical oxygen generator factory low-pressure oxygen chambers, medical air purification equipment, and undertakes projects such as hospital operating room and laboratory purification, cleanroom construction, radiation protection engineering, and medical wastewater treatment engineering.medical oxygen plant manufacturer