In the intricate ecosystem of modern healthcare, the consistent and reliable provision of medical oxygen stands as a non-negotiable cornerstone, directly impacting patient outcomes and operational efficiency. A robust medical oxygen supply system is not merely a utility; it is a life support infrastructure, essential for an array of medical procedures from critical care and surgical interventions to chronic respiratory support and emergency response. The demands on these systems have surged exponentially, driven by global health crises, an aging population, and the expansion of healthcare services into remote regions. Traditional methods, often reliant on high-pressure cylinders or bulk liquid oxygen, face inherent limitations regarding logistics, cost volatility, and the omnipresent risk of supply chain disruptions. These challenges underscore the pressing need for advanced, on-site oxygen generation solutions that offer unparalleled reliability, purity, and cost-effectiveness. The paradigm shift towards decentralized, generator-based systems represents a strategic move for healthcare providers seeking to enhance resilience and ensure an uninterrupted flow of this vital gas. Investing in a state-of-the-art system signifies a commitment to superior patient care, operational autonomy, and long-term sustainability within a rapidly evolving medical landscape. The decision to implement or upgrade such a system necessitates a comprehensive understanding of technological advancements, market offerings, and bespoke customization possibilities to align perfectly with a facility's unique operational demands and future growth trajectory.

The Unfolding Global Demand and Its Health Implications

The global healthcare sector has witnessed an unprecedented surge in demand for medical oxygen, a trend significantly amplified by recent worldwide health emergencies. Before 2020, approximately 500,000 hospital beds globally required supplemental oxygen, a figure that dramatically increased by an estimated 400% during peak periods of respiratory illness outbreaks. This surge not only strained existing supply chains but also highlighted critical vulnerabilities, leading to tragic shortages in numerous regions. Studies from the World Health Organization suggest that inadequate oxygen access contributes to over 1 million preventable deaths annually, particularly in low- and middle-income countries, where consistent supply infrastructure is often nascent or non-existent. The financial implications are equally staggering; facilities relying solely on external bulk oxygen suppliers can see up to 20-30% of their operational budget allocated to oxygen procurement, often complicated by transportation costs, cylinder rental fees, and emergency delivery surcharges. Moreover, the environmental footprint of frequent deliveries and the energy consumption for liquefaction and transportation also present long-term sustainability concerns. The critical need for oxygen extends beyond emergency rooms, permeating operating theaters, intensive care units, neonatal units, and even specialized clinics. Without a reliable, on-demand supply, hospitals face the grim reality of rationing care, postponing essential surgeries, and compromising patient safety. This confluence of escalating demand, logistical fragility, economic burden, and environmental considerations paints a stark picture, unequivocally emphasizing the urgency for healthcare institutions worldwide to re-evaluate and fortify their oxygen supply infrastructure with robust, self-sufficient solutions.

Revolutionizing Healthcare: Technical Superiority in Oxygen Generation

Modern medical oxygen generation systems represent a significant leap forward, leveraging sophisticated technologies to provide an on-site, continuous supply of high-purity oxygen. At the core of many contemporary systems is Pressure Swing Adsorption (PSA) technology, an ingeniously simple yet profoundly effective method. PSA works by separating oxygen from compressed air using a molecular sieve that preferentially adsorbs nitrogen, argon, and other trace gases. The process typically involves two adsorber vessels operating in alternating cycles: one vessel produces oxygen while the other regenerates. This continuous cycle ensures an uninterrupted supply. Key technical advantages of these advanced systems include remarkable oxygen purity, typically achieving 93% ± 3% (meeting USP and European Pharmacopoeia standards for medical use), which is critical for patient safety and treatment efficacy. Furthermore, modern systems boast enhanced energy efficiency, with some units consuming up to 30% less power per cubic meter of oxygen compared to older models, directly translating into significant operational cost savings. They are designed for high reliability, often incorporating redundant components and advanced monitoring systems that provide real-time performance data and predictive maintenance alerts. Features like fully automated operation minimize the need for manual intervention, while remote monitoring capabilities allow for off-site diagnostics and control, optimizing uptime. Scalability is another crucial benefit; modular designs enable easy expansion of oxygen capacity as a facility's needs grow, avoiding costly overhauls. Integrated air compressors, air dryers, filtration systems, and oxygen buffer tanks ensure a complete, self-contained solution, reducing reliance on multiple vendors and complex installations. These technical advancements collectively establish on-site generation as a superior alternative, offering unparalleled control, safety, and economic benefits over traditional external oxygen procurement methods.

Navigating the Market: A Comparative Analysis of Medical Oxygen System Providers

Choosing the right medical oxygen supply system requires a thorough evaluation of available solutions and providers. The market offers a range of manufacturers, each with distinct strengths in technology, service, and customization. Understanding these differences is paramount to selecting a system that aligns with a healthcare facility's specific needs, budget, and long-term goals. Key factors for comparison include oxygen purity levels, system capacity (liters per minute or cubic meters per hour), energy consumption efficiency, maintenance requirements, and the comprehensiveness of after-sales support. Below is a comparative table illustrating typical distinctions between different provider approaches. This table aims to provide a generalized overview, as specific models and features will vary greatly:

|

Feature/Provider Type |

Provider A (High-End Specialist) |

Provider B (Mid-Market Integrator) |

Provider C (Cost-Effective Solution) |

|

Oxygen Purity (Medical Grade) |

93% ± 3% (Consistent, highly stable) |

93% ± 3% (Generally stable) |

90% – 95% (May fluctuate slightly) |

|

Capacity Range (LPM) |

50 – 5000+ LPM (Highly scalable modular units) |

20 – 2000 LPM (Good scalability) |

10 – 500 LPM (Limited modularity) |

|

Energy Efficiency (kWh/m³) |

Excellent (0.8 – 1.2 kWh/m³, advanced controls) |

Good (1.0 – 1.5 kWh/m³, standard controls) |

Moderate (1.3 – 2.0 kWh/m³, basic controls) |

|

Maintenance & Service |

Comprehensive global support, remote monitoring, predictive maintenance |

Regional support, standard service contracts, some remote diagnostics |

Local technicians, basic warranty, limited remote support |

|

Features & Technology |

Redundant systems, advanced HMI, IoT integration, containerized options |

Automated operation, purity alarms, standard backup options |

Manual control options, basic alarms, cylinder backup connection |

|

Initial Investment |

Higher |

Medium |

Lower |

|

Total Cost of Ownership (TCO) |

Low (due to efficiency & longevity) |

Medium (balanced) |

Higher (due to less efficiency & more maintenance) |

Beyond these technical specifications, it's crucial to assess each provider's track record, compliance with international medical standards (e.g., ISO 13485, CE marking), and their capability to offer complete turnkey solutions including installation, training, and ongoing technical support. A thorough due diligence process ensures not just a compliant and functional system, but a long-term partnership with a provider capable of supporting a healthcare facility's evolving oxygen needs.

Precision Engineering: Developing Tailored Oxygen Solutions

Recognizing that no two healthcare facilities are identical, the provision of an effective medical oxygen supply system often hinges on the ability to develop a truly tailored solution. Customization goes far beyond simply matching capacity to current demand; it involves a holistic assessment of a facility's unique operational environment, infrastructure, budget constraints, and future expansion plans. A comprehensive customization process typically begins with an in-depth site survey and a detailed demand analysis. This involves evaluating the number of beds, types of departments (ICU, OR, ER, general wards), peak and average oxygen consumption rates, and any existing oxygen infrastructure. For instance, a small rural clinic might require a compact, containerized PSA unit with integrated cylinders for backup, emphasizing ease of deployment and minimal footprint. In contrast, a large multi-specialty hospital campus may need multiple high-capacity PSA generators, a centralized distribution network, extensive manifold backup systems, and seamless integration with building management systems for advanced monitoring and control. Customization also extends to the physical layout, noise considerations for sensitive areas, power supply requirements, and even specific environmental conditions (e.g., high altitude, extreme temperatures) that might necessitate specialized compressor or dryer configurations. Furthermore, providers can integrate various safety features, such as automated switchover systems, real-time purity analyzers, dew point sensors, and comprehensive alarm systems that alert staff to any deviations from operational parameters. The ability to design modular systems allows for future-proofing, ensuring that as patient volumes grow or new departments are added, the oxygen supply can be scaled up efficiently without needing to replace the entire system. This bespoke approach ensures optimal performance, maximum safety, and the most cost-effective solution over the system's operational lifespan, providing peace of mind for healthcare administrators and clinical staff alike.

Transforming Operations: Diverse Applications in Action

The versatility and reliability of on-site medical oxygen supply systems have made them indispensable across a wide spectrum of healthcare applications, each demonstrating unique benefits and operational transformations. In large urban hospitals, these systems provide a continuous, high-volume supply for extensive medical gas pipelines, supporting dozens of operating rooms, hundreds of ICU beds, and multiple specialized clinics. One major teaching hospital in Southeast Asia, facing escalating costs and logistical challenges with bulk liquid oxygen, installed a dual-PSA system with a combined capacity of 1500 LPM. Post-installation analysis revealed a 35% reduction in annual oxygen expenses and a dramatic improvement in supply stability, virtually eliminating critical delivery delays that previously jeopardized patient care. For remote clinics and disaster relief efforts, containerized or mobile oxygen generators prove invaluable. A humanitarian organization deploying medical teams to a conflict zone successfully utilized a compact, trailer-mounted PSA unit, generating 50 LPM of medical-grade oxygen. This self-contained unit, powered by a generator, allowed them to establish fully functional critical care facilities in areas with no existing infrastructure, providing life-saving respiratory support to over 200 patients within the first month of operation. In veterinary hospitals, which have equally stringent oxygen purity requirements for animal anesthesia and critical care, a specialized PSA system with a capacity of 100 LPM significantly reduced the dependency on numerous, bulky oxygen cylinders, freeing up valuable storage space and improving workflow for veterinary technicians. Furthermore, in specialized clinics such as hyperbaric oxygen therapy centers, consistent high-purity oxygen is paramount. A clinic in North America reported a 20% increase in patient throughput and a more stable treatment environment after replacing their cylinder manifold system with a dedicated PSA generator, allowing for more consistent and efficient therapy sessions. These diverse examples underscore how customized, on-site oxygen generation systems are not just a luxury but a fundamental tool for enhancing healthcare delivery, improving resilience, and ultimately saving lives across various medical settings.

Securing the Future: Optimizing Your Medical Oxygen Supply System Investment

The decision to invest in a modern medical oxygen supply system is a strategic imperative that extends far beyond immediate operational needs; it is an investment in the long-term resilience, financial health, and quality of patient care for any healthcare institution. The rapid advancements in PSA technology, coupled with intelligent monitoring and predictive maintenance capabilities, mean that contemporary systems offer unparalleled efficiency and reliability, significantly reducing the total cost of ownership over their operational lifespan. By mitigating reliance on external suppliers, facilities gain greater control over their oxygen supply, shielding them from market volatility, logistical disruptions, and the environmental impact associated with transportation. Furthermore, the modular design and scalability inherent in many modern systems ensure that today's investment can adapt to tomorrow's growth, protecting against obsolescence and facilitating seamless expansion. As healthcare continues to evolve, encompassing more complex treatments and a growing global patient population, the demand for consistent, high-purity medical oxygen will only intensify. Proactively adopting an advanced on-site generation system positions a facility at the forefront of medical readiness, enhancing its capacity to respond effectively to routine demands and unforeseen crises alike. Ultimately, optimizing a medical oxygen supply system investment means choosing a solution that is technically robust, economically viable, environmentally sustainable, and backed by a trustworthy partner committed to long-term support and continuous innovation. This comprehensive approach safeguards both patient well-being and institutional integrity, solidifying a foundation for sustained excellence in healthcare delivery.

Frequently Asked Questions about Medical Oxygen Supply Systems

Here are some common questions regarding medical oxygen supply systems:

1. What is a Medical Oxygen Supply System?

A medical oxygen supply system is an integrated infrastructure designed to generate, store, and deliver medical-grade oxygen to healthcare facilities. Modern systems often use Pressure Swing Adsorption (PSA) technology to produce oxygen on-site from ambient air, ensuring a continuous and reliable supply.

2. Why is an on-site PSA Medical Oxygen System considered superior to traditional cylinder or bulk liquid oxygen?

On-site PSA systems offer numerous advantages including significant cost savings (eliminating delivery fees, cylinder rentals), enhanced supply reliability (no reliance on external logistics), higher safety (lower pressure storage), and reduced environmental footprint. They provide autonomy and scalability.

3. What purity level is required for medical-grade oxygen?

Medical-grade oxygen must meet specific purity standards, typically 93% ± 3% (ranging from 90% to 96%) oxygen concentration, with the remainder being argon and nitrogen. This purity level is specified by pharmacopoeial standards such as USP and European Pharmacopoeia.

4. How is the capacity of a Medical Oxygen Supply System determined?

Capacity is determined by the peak oxygen demand of the facility, which depends on factors like the number of beds, types of medical services (ICU, OR, ER), average and peak consumption rates, and a safety margin for future expansion. It's measured in liters per minute (LPM) or cubic meters per hour (m³/h).

5. What components typically make up a complete on-site Medical Oxygen Supply System?

A complete system usually includes an air compressor, air dryer, pre-filters, activated carbon filter, PSA oxygen generator, oxygen buffer tank, oxygen purity analyzer, bacteria filter, and a control system. Many systems also integrate a medical air manifold for backup.

6. Are Medical Oxygen Supply Systems safe?

Yes, modern medical oxygen supply systems are designed with multiple safety features, including purity alarms, pressure monitors, automatic shut-off valves, and redundant components. They operate at lower pressures than high-pressure cylinders, inherently reducing certain risks. Proper installation and maintenance are crucial for safety.

7. What is the typical lifespan and maintenance requirement for a PSA Oxygen Generator?

With proper maintenance, a PSA oxygen generator can have an operational lifespan of 15-20 years or more. Routine maintenance typically involves replacing filters, checking valve functions, and monitoring molecular sieve performance, usually on an annual or semi-annual basis as per manufacturer guidelines.

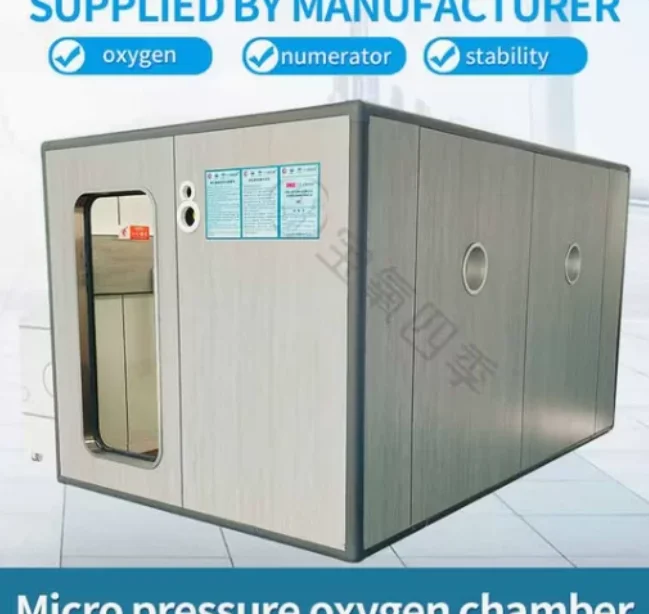

Hebei Lixin Medical Engineering Co., Ltd. was established in 2011. medical oxygen generator manufacturers The company specializes in the production and sales of medical central gas supply systems,medical oxygen generator manufacturers medical molecular sieve oxygen generation equipment, medical oxygen generator factory low-pressure oxygen chambers, medical air purification equipment, and undertakes projects such as hospital operating room and laboratory purification, cleanroom construction, radiation protection engineering, and medical wastewater treatment engineering.medical oxygen plant manufacturer