Why 2.0 ATA Rigid Home Chambers Are Stealing the Spotlight

If you’ve watched the hyperbaric market over the past five years, you’ve probably noticed the quiet shift from soft shells to compact rigid systems. The sweet spot? Hyperbaric Chamber 2.0 Ata. To be honest, 2.0 ATA feels like the new “practical maximum” for home users—enough therapeutic pressure without the infrastructure demands of hospital monoplace units. I’ve toured a few factories; what surprised me is how far build quality has come, especially from northern China’s pressure-vessel corridor.

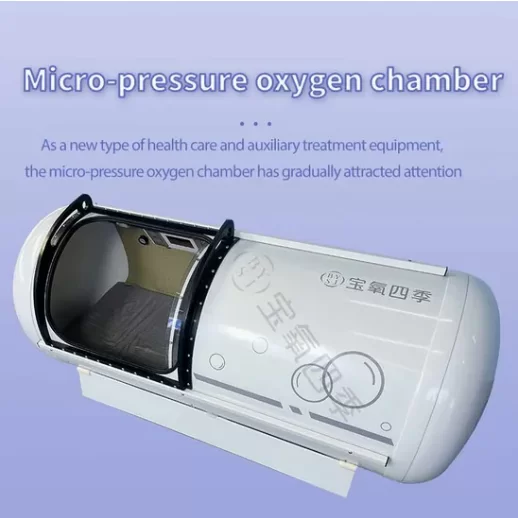

What’s inside the 2.0ATA Customizable Rigid Single-Person Chamber

Originating from 888 Kaiyuan Road, Jizhou District, Hengshui City, Hebei Province, this unit blends marine-grade alloys with medical oxygen hardware, then layers in home-friendly controls. Many customers say the learning curve is shorter than expected—pressurize, breathe, relax.

| Pressure Rating | 2.0 ATA (≈202 kPa); control stability ±0.02 ATA (real-world may vary) |

| Construction | Rigid shell, marine-grade aluminum frame, acrylic viewport; CNC-welded, NDT-inspected |

| Oxygen Source | 93% ±3% concentrator; optional dual flow 5–10 L/min combined |

| Noise | ≈58–62 dBA at 1 m in a typical room |

| Power | AC 110–240 V, 50/60 Hz; ≈700–900 W under load |

| Dimensions | Single-person; footprint suitable for home office or spare room (exact sizes vary by customization) |

| Safety | Pressure relief valves, O2 monitoring, emergency depressurization; built to PVHO and NFPA 99 guidance |

Process, testing, and service life (the nuts and bolts)

Materials: marine-grade aluminum shell, anti-static interior lining, medical-grade fittings, silicone gaskets rated for O2 exposure. Methods: CNC welding, bead blasting, powder-coat, then non-destructive testing (dye penetrant + radiography on critical seams). Hydrostatic and pneumatic tests typically run at ≥1.25–1.5× working pressure; leak rates verified at ≤0.5% vol/hr at 2.0 ATA in factory trials. Service life is quoted around 10–15 years with annual inspections; gaskets and filters have 12–24 month cycles depending on use.

Where it actually gets used

Home recovery suites, boutique wellness studios, physiotherapy rooms, and—interestingly—small sports academies. Users report post-exercise recovery, general wellness routines, and focus sessions. I guess the portability aspect of a rigid unit wasn’t obvious until I saw one wheeled through a townhouse doorway.

Customization options

Upholstery colors, viewport size, extra accessory ports, upgraded concentrator capacity, external display, and antimicrobial interior fabrics. Branding panels are possible for studios. The company can also tune compressor profiles for quieter night sessions—handy.

Vendor snapshot (what buyers compare)

| Vendor | Shell Type | Pressure | Noise | Cert/Standards |

|---|---|---|---|---|

| StoreOxygen (this model) | Rigid | 2.0 ATA | ≈58–62 dBA | PVHO-1, NFPA 99 guidance, ISO 13485 QMS |

| Vendor A (typical soft shell) | Flexible | 1.3–1.5 ATA | ≈50–55 dBA | General electrical; fewer pressure-vessel refs |

| Vendor B (clinic-grade) | Rigid | 2.0–3.0 ATA | ≈60–68 dBA | PVHO-1, IEC 60601-1, higher infra needs |

Field notes and case snippets

Hyperbaric Chamber 2.0 Ata in a suburban home gym: 45–60 minute evening sessions, reported quieter sleep and quicker “leg freshness” after runs (subjective, of course). Small physio studio: used on a rotation with compression boots; owner liked the emergency depressurization control and the easy-clean interior. Feedback trends: “sturdy,” “predictable pressure ramp,” and “less hum than expected.”

Compliance, testing data, and standards

Built under an ISO 13485 quality system; electrical sub-systems aligned with IEC 60601-1; oxygen hardware follows ISO 7396-1 principles; pressure boundary designed to ASME PVHO-1 concepts with hydro/pneumatic tests; fire safety framed by NFPA 99 guidance for oxygen-enriched environments. Factory test cards I reviewed showed pressure stability within ±0.02 ATA and leak rates meeting the stated thresholds. Always verify local regulatory status—markets differ.

Hyperbaric Chamber 2.0 Ata advantages in short: rigid safety margins, crisp pressure control, realistic home footprint, and customization without clinic-level overheads. It’s not flashy—and that’s exactly the point.

Authoritative references

- ASME PVHO‑1: Safety Standard for Pressure Vessels for Human Occupancy – https://www.asme.org

- NFPA 99: Health Care Facilities Code (Oxygen-enriched atmospheres) – https://www.nfpa.org

- IEC 60601‑1: Medical Electrical Equipment – https://webstore.iec.ch

- ISO 13485: Medical Devices QMS – https://www.iso.org/standard/59752.html

- ISO 7396‑1: Medical gas pipeline systems – https://www.iso.org

- UHMS Guidelines for Hyperbaric Facilities – https://www.uhms.org

Hebei Lixin Medical Engineering Co., Ltd. was established in 2011. medical oxygen generator manufacturers The company specializes in the production and sales of medical central gas supply systems,medical oxygen generator manufacturers medical molecular sieve oxygen generation equipment, medical oxygen generator factory low-pressure oxygen chambers, medical air purification equipment, and undertakes projects such as hospital operating room and laboratory purification, cleanroom construction, radiation protection engineering, and medical wastewater treatment engineering.medical oxygen plant manufacturer